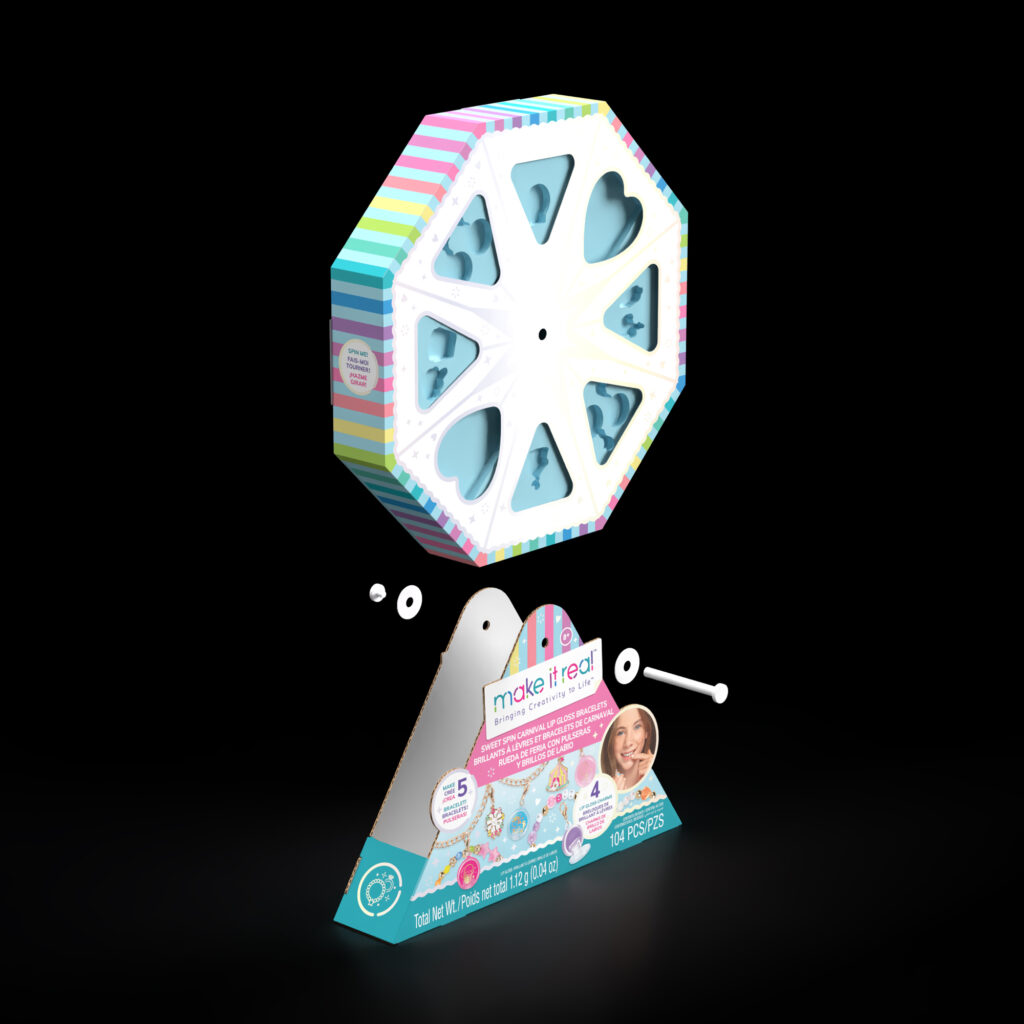

During a development meeting one day, we were on the topic of having a carnival theme for one of our items. Looking at inspiration images, I saw a cute ferris wheel and commented on it, to which one of the designers joked “Could you imagine if we had one as a box?”

That was it. I had to jump to the challenge because having a functional spinning ferris wheel as product packaging would be such an accomplishment to develop for mass production. “No problem!” I said!

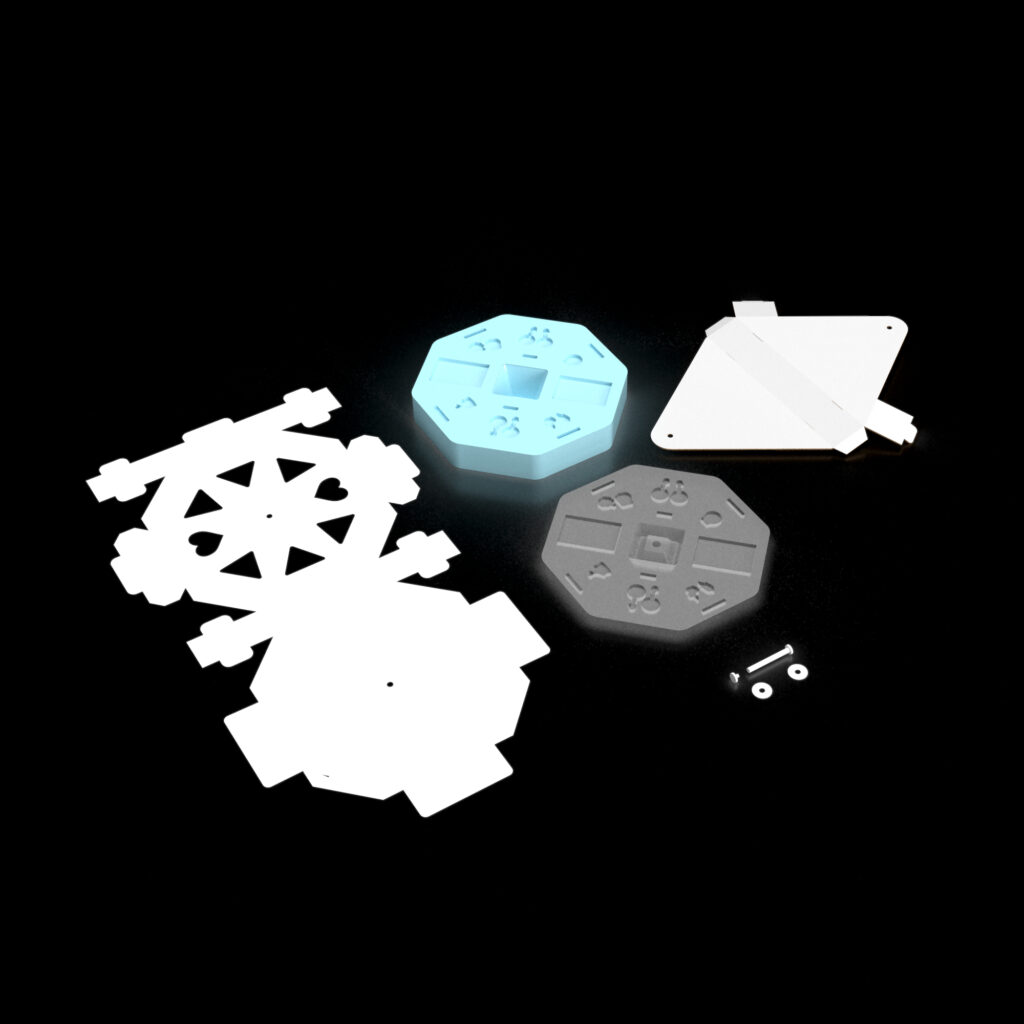

Keeping the components down to a minimum, the packaging assembly consists of a main E-Flute base, colour main blister, clear blister snap cover, the octagonal wheel body box, and finally, the axel screw with washers to attached the body to the base at a pivot point.

Simplicity was key to keeping both material costs down, and to keep assembly in production as easy as possible, while still being robust enough to survive the gauntlet of shipping, ground transit, and finally, the torture of kids spinning it at retail.

It’s hard to resist spinning the final construction, the compelling functional display makes this stand out from standard packaging sourrounding it on retail shelves. It amplifies the carnival graphic theme to the next level too, creating an experience with tons of charm which seals the deal for encouraging the sale and collectable factor.

Project Involvement:

- Initial concept ideation and pitch

- Validating dimensional requirements

- Materials specs consultation for production quoting

- Dieline design, sampling, and refinement

- Pre-production QC direction to factory

Substrates Used:

20pt art card main body structure

E-Flute base structure

Clear PET thermoformed blister cover

Coloured PET thermoformed blister

ABS screw rivet axle